DO I NEED MY OWN SYSTEM? Maybe!

DOES CULLIGAN HAVE A DEIONIZATION EXCHANGE PROGRAM? Absolutely!

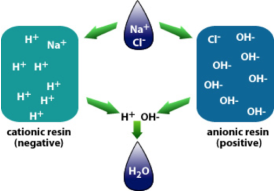

Deionization systems can be expensive to buy, install, and most importantly maintain but Culligan delivers the expertise and integration you need.

- Culligan also provides Deionization Exchange Service that eliminates capital investment while providing all the benefits of your own DI process without regulatory training and constraints.

- DI Exchange tanks will be plumbed directly into your water supply and can be exchanged as needed.

- Regardless of the flow needed, once the resin tanks are exhausted, they’re simply exchanged on a regular schedule and regenerated off-site.

No matter which option is right for you and your business, Culligan will help you determine your requirements and provide an affordable solution.